What is MEMS Technology?

Micro-Electro-Mechanical Systems, or MEMS is a technology that can be defined as miniaturized mechanical and electro-mechanical elements at waffer scale. This allows MEMSs technology to be embedded on chips that can be integrated on a printed circuit, like any other electronics component.

Devices are composed of electromechanical elements (moving or not) under the control of integrated microelectronics.

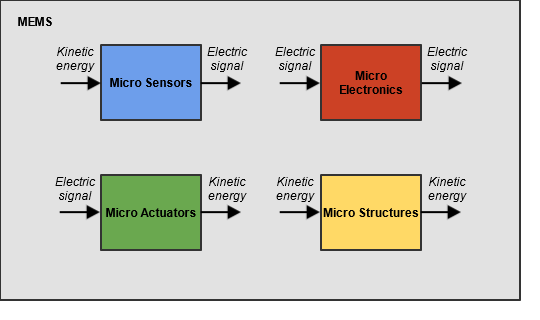

Functional elements of MEMS are miniaturized structures, sensors, actuators and microelectronics. Microsensors and microactuators are categorized as transducers which are devices converting a measured mechanical signal in electrical one.

Micro sensors can be used now for various measurements such as temperature, pressures, magnetic fields or inertial measurements.

High quality MEMS components have been selected for our IMUs. This MEMS technology provides many advantages over competing technologies such as mechanical or FOG gyroscopes, or servo accelerometers:

- A miniature design provides smaller, lighter products, enabling new applications to be covered.

- This technology is very robust and provides much higher shock resistance as well as maintenance free operation.

- MEMS designs provide cost effective solutions compared to other technologies such as FOG or RLG.

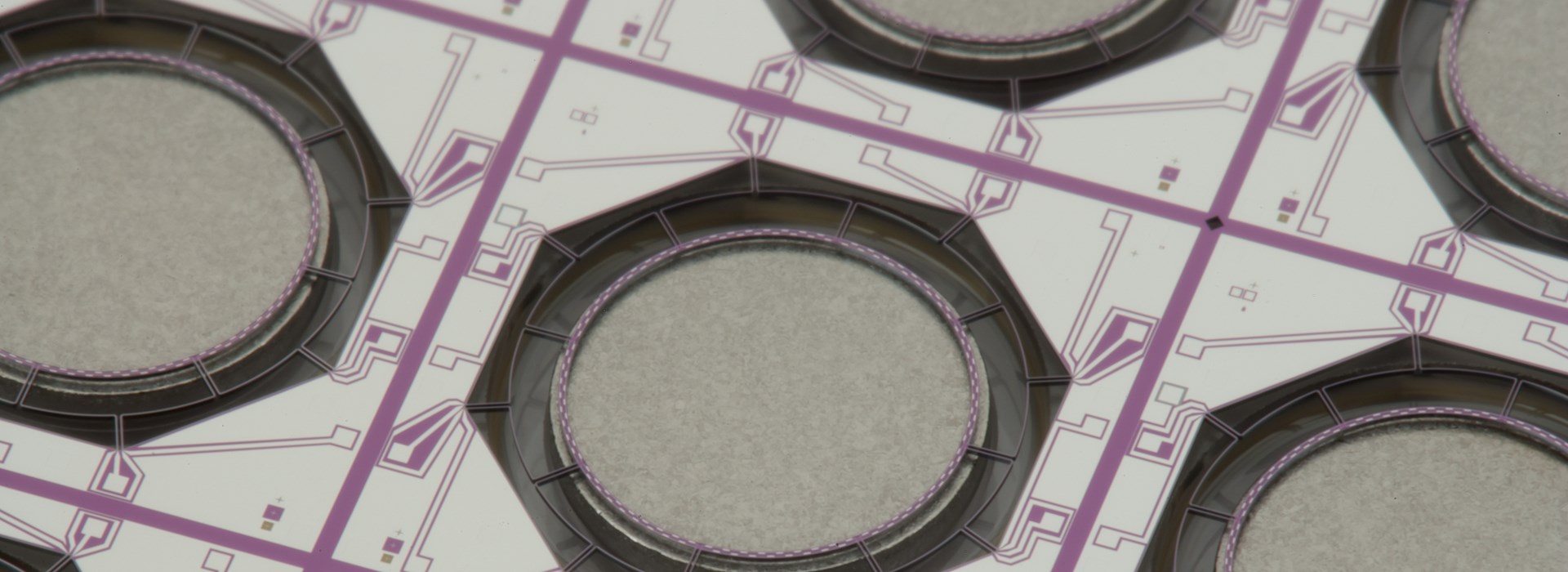

MEMS Ring of a gyroscope - Courtesy of Silicon Sensing

MEMS perfomance

Although the same MEMS technology is used for consumer applications such as smart-phones and tablets, there is a very large performance gap between low cost MEMS and navigation grade MEMS sensors. SBG Systems only selects high performance sensors only.

Vibration Handling

SBG Systems IMUs has been designed for harsh environments. Specific developments led to efficient vibration handling.

When exposed to vibrations, an accelerometer or gyroscope will have some increased bias. This vibration effect on accelerometer is called VRE. So a good starting point is to choose sensors that have low VRE in order to sustain higher levels of vibrations.

The second point is to design efficient hardware and software signal processing, particularly high frequency sampling (>1kHz) will prevent aliasing issues and improve sensor data resolution.