Download PDF

Download page Lever Arm Estimation.

Lever Arm Estimation

Introduction

Qinertia features a powerful module used to estimate and refine automatically mechanical installation parameters such as the GNSS primary and secondary antenna lever arms. You can use this module if you have no way to precisely measure lever arms or alignment but also to check entered settings consistency.

The automatic estimation algorithm needs enough dynamics and good GNSS conditions to observe correctly the lever arms. Please read the dedicated Lever arms & alignment calibration article to get more details.

General Concepts

SBG Systems Inertial Navigation System (INS) as well as Qinertia can estimate several mechanical installation parameters such as the GNSS primary and secondary lever arms. This estimation is done using additional observation states in the INS Extended Kalman Filter (EKF).

To estimate lever arms and mechanical alignments, a specific mode has to be enabled in the navigation filter. When this mode is enabled, the navigation filter will try to find the best lever arms and alignment parameters that minimize INS / GNSS position discrepancies.

In this mode, the overall INS solution is less accurate and robust so you should only use this mode to estimate mechanical parameters and not to get an INS solution. If you are also interested in the INS solution, you should execute a second processing without this specific mode enabled and with updated lever arm / alignment parameters.

Always try to input an initial guess for all lever arms. The more accurate the initial guess is the better and faster the estimation will be.

Acquisition Pattern

The navigation filter need some motion and dynamics to correctly estimate lever arms and alignment parameters. For example, if there is no roll/pitch motion it will be almost impossible to correctly estimate the lever arm vertical component.

Moreover, the INS need an accurate RTK/PPK position to refine correctly the lever arms. The INS tries to estimate lever arms with an accuracy of 1 cm so the INS obviously need an input position with the same level of accuracy.

SBG Systems strongly recommends to have a dedicated acquisition to estimate the lever arms using figure of 8-patterns in a good open sky environment.

Real Time vs Post Processed

All SBG Systems Inertial Navigation Systems have a built in mechanical installation parameters estimation module so you can do it in real time. However, post-processing offers several major advantages over a real time estimation.

Qinertia can process the same acquisition in forward and backward directions and process it three times. As a result, the lever arm can converge to the right values much faster than using a real time solution.

More importantly, if you can only apply low dynamics and motions, such as for a big vessel, Qinertia can estimate the lever arms accurately while the real time solution could just fail. Post processing can also be mandatory if you can't have in real time a RTK position quality.

Finally, Qinertia gives more detailed quality control indicators to assess the estimation accuracy and reliability.

Using Qinertia GUI

This is the most common way to use Qinertia to estimate mechanical installation parameters with full control on all parameters as well as plenty real time quality indicators and feedback.

Enable Estimation Mode

The mechanical estimation is done through a dedicated processing run and you should first enable this mode from the main project processing settings as shown below:

GNSS Secondary Antenna

Qinertia can estimate the GNSS secondary antenna (true heading) from an initial guess or from scratch if the lever arm is completely unknown. You should configure correctly this setting from the Project Settings→GNSS page as shown below:

Heading Mode

If you select Heading Mode to Dual Antenna (auto lever arm), Qinertia will also automatically enable the estimation mode.

Select parameters to estimate

As soon as you start a processing while the estimation mode is enabled, Qinertia should ask which parameters / lever arm should be estimated or not. This is very helpful if, for example, you have a precise primary GNSS lever arm measurement and don't want to change this value but don't know the secondary GNSS lever arm.

Process the mission

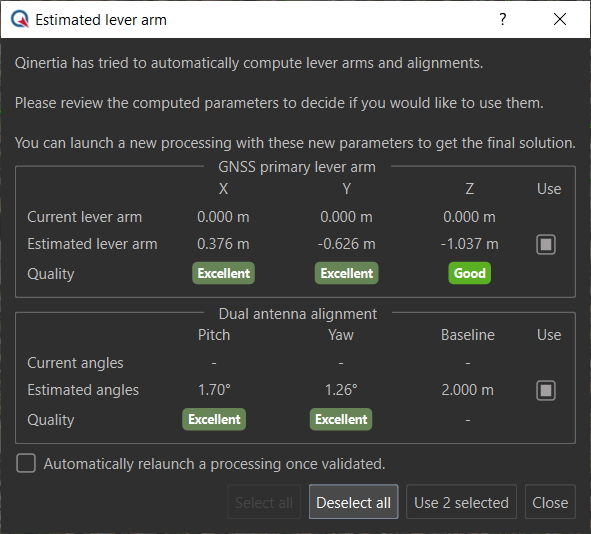

Qinertia processes the mission and try to estimate each enabled parameter. Once the processing is done, Qinertia displays mechanical estimation results with initial / estimated lever arm as well as quality indicators as shown below:

The default display shows easy to understand quality metrics computed using the estimated parameter standard deviation and stability. If you click on the Quality label, you can access these advanced metrics as shown on the screenshot below:

Apply the estimated parameters

During the auto estimation processing, Qinertia focus on lever arm estimation and not on the INS solution accuracy and reliability. You shouldn't use the INS solution that has been computed for the automatic estimation but rather launch a new processing with the lever arms refined by Qinertia.

If you are happy with the estimated lever arms and alignments, simply check the use checkbox to update the project configuration with the new values. You can then launch right away the final INS computation or close the dialog box and do it later by yourself

Mechanical Estimation Report

You can review the latest mechanical estimation report by clicking on the processing progress indicators.

Using Command Line Interface

Qinertia also provides a full featured Command Line Interface (CLI) that can be used to automate mechanical installation parameters estimation. For each mechanical parameter to estimate, the preciseSetup flag has to be set to false in the JSON process file.

You can then use Qinertia CLI to process the project and an additional block in the processing Session report JSON file is added with all details regarding each estimated parameter.

Please check the GitHub Lever Arm Estimation Project samples to quickly start using the CLI.

Qinertia Lever Arm Estimation Tool

A dedicated GUI tool is shipped with Qinertia especially designed to estimate mechanical installation parameters. This step-by-step wizard relies on Qinertia CLI to only expose the minimum configuration and information needed for this task.

This tool should be seen as a powerful alternative to the real time mechanical estimation module built-in High Performance INS product such as Navsight, Quanta, Ekinox and Apogee.

This wizard combines the real time GNSS positions with the IMU data in a loosely coupled manner to keep things simple. To work, you need a good real time GNSS RTK or PPP solution as for the real time mechanical estimation module.

To use this tool, simply execute the dedicated Qinertia-lever-arm executable, drag&drop your acquisition and follow the step-by-step wizard.

Qinertia or Qinertia-lever-arm?

If you don't have a good real time GNSS RTK or PPP solution, you should go for a tightly coupled solutions and use the full Qinertia software.